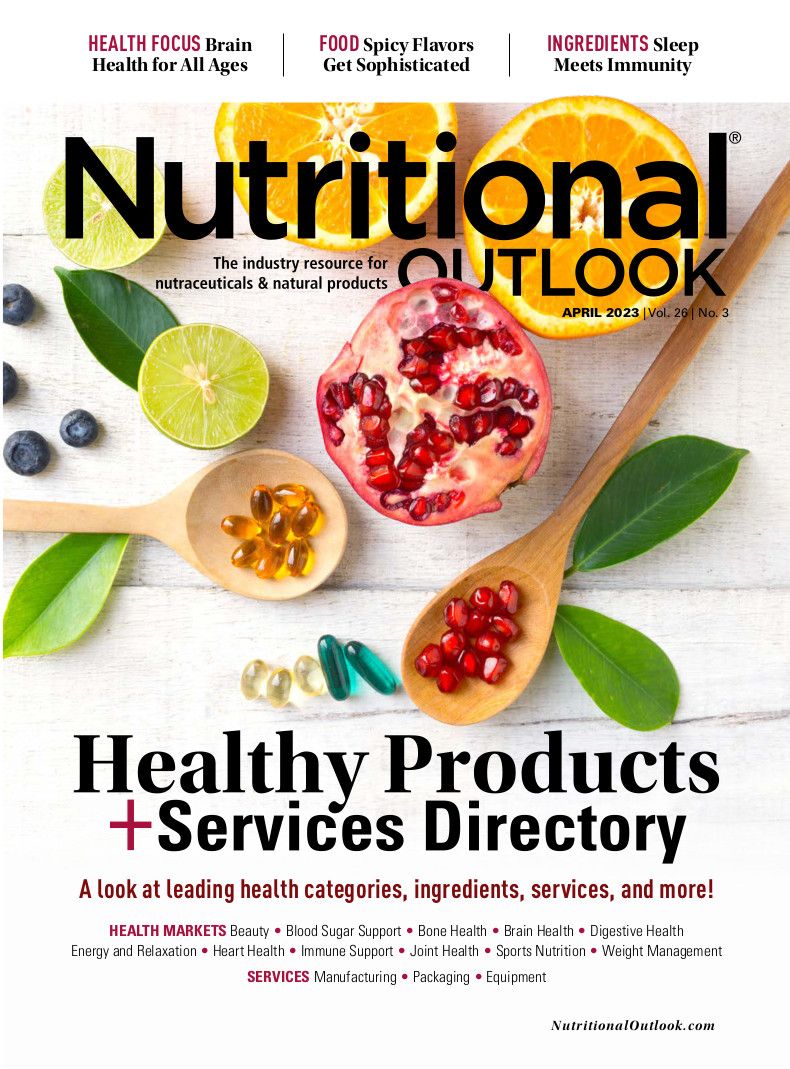

Contract manufacturers offer more customer support to help nutraceutical brands compete

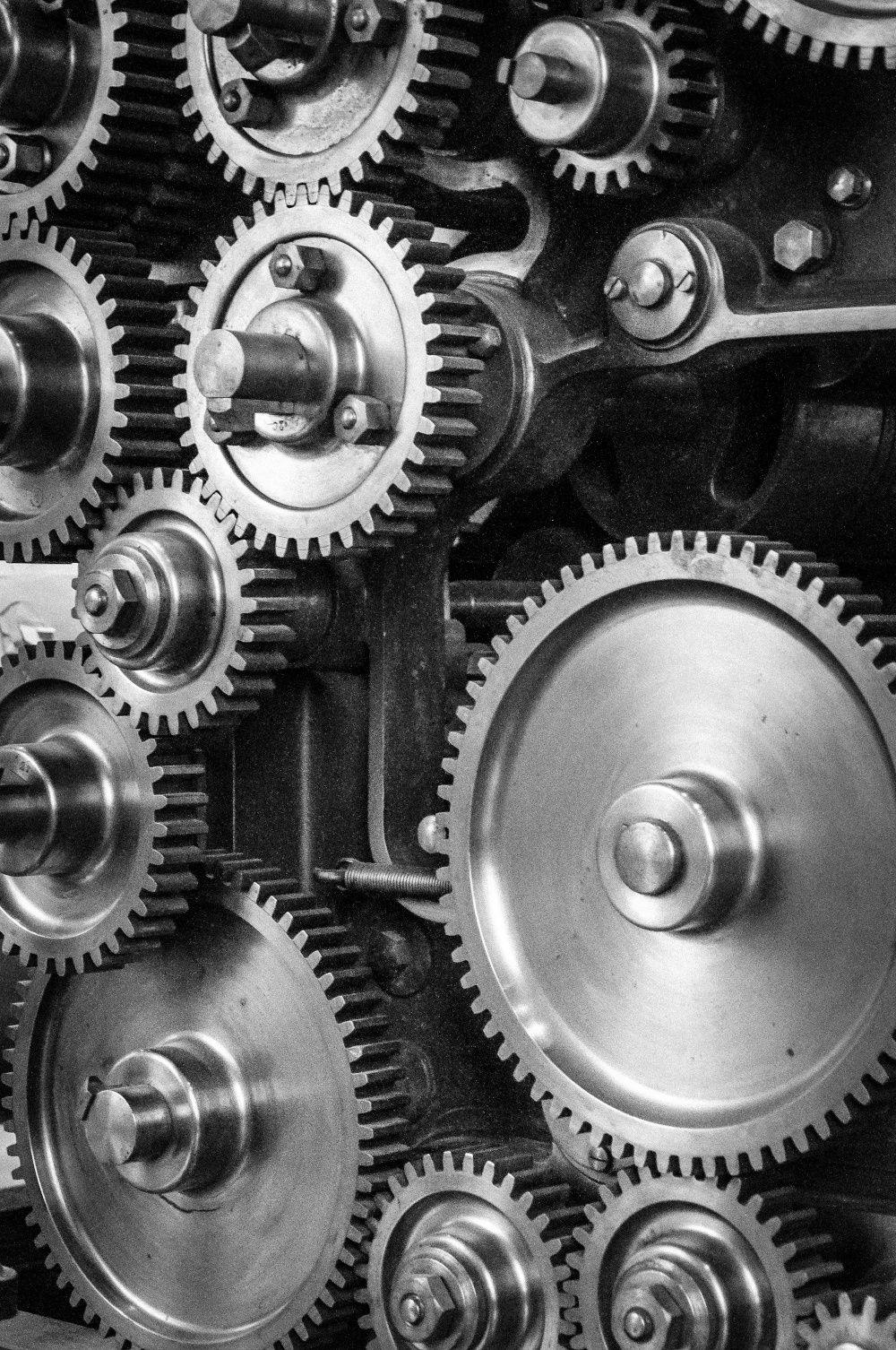

Contract manufacturers are making major investments to grow their capabilities.

© Aleksandr Matveev / Stock.adobe.com

The demand for contract services is growing, and contract manufacturers are making major investments to better meet demand and grow their capabilities. According to Maite Jeanroy, marketing and communications manager at Activ’Inside (Beychac-et-Caillau, France), the pandemic, as well as rising healthcare costs, were major factors fueling demand for dietary supplements.

“Consumers are now more than ever aware of the importance of personal health and well-being and are concentrating on the prevention part of health—which is where food supplements play a role,” says Jeanroy. This growing demand creates opportunity, but brand owners are often limited in their resources to quickly and efficiently formulate and market the innovative products that consumers want.

“Alongside this growing demand is the need for brand owners to develop food supplements that tick all of the requirements such as scientifical, analytical, regulatory, and marketing aspects before hitting the shelf,” Jeanroy explains. “One of the many problems that most brand owners face is having different parties for different fields of expertise, and this has also influenced our customers’ requests for a while now.”

The pressure on brand owners creates opportunity for contract manufacturers while also pushing the limits of their own resources as brands need a partner that will provide end-to-end support. In the case of Activ’Inside, the company was predominantly a supplier of proprietary extracts but saw an opportunity in committing more resources to contract manufacturing. “While they used to ask us for innovative and effective ingredients to formulate, they are now requesting complete support, from the choices of ingredients to the realization of the finished product, all with a marketing perspective and regulatory validation. The need for a single-point contact is the main reasoning behind Activ’Inside Manufacturing,” says Jeanroy. As a result, the company invested $13 million into a 3,200-sq-m contract manufacturing facility.

In addition to the growing demand for more innovative dietary supplement products, the pandemic also caused manufacturers to lose confidence in the global supply chain. “There was a lot of pent-up demand from our customer base for local production,” says Douglas Brown, vice president of Sirio Americas and Best Formulations’ new chief commercial officer. Sirio recently acquired Best Formulations, which established for the company a new headquarters and manufacturing operation in North America. “This means we can work with global customers in more than one market,” Brown says.

Having experts that help you formulate a product while also commanding a reliable supply chain is invaluable, particularly in these volatile economic times.

Keeping Up

Novel dosage formats such as gummies are a major driver in the dietary supplement industry currently. For consumers, gummies are palatable and easy to take, and for manufacturers, they create a segment with a high level of adherence and therefore customer retention. As with all trends, however, developing a competitive product can be difficult, especially for something as specialized as gummy manufacturing.

Few companies are as well acquainted with the growing demand for gummies as Sirio, which opened its newest gummy manufacturing plant in Ma’anshan, China, in 2018. “Demand has increased exponentially since then as customers recognize that gummies are the most consumer-friendly format,” explains Brown. “We have been able to expand the depth of our offerings as well with plant-based, bi-layer, center-filled, swirled, certified-organic, and aerated gummies now available. Sirio is constantly innovating and developing new formulations for gummies with the deepest capabilities of any contract development and manufacturing company (CDMO), particularly in relation to novel gummies with the best organoleptic properties.”

Plant-based formulations across multiple product categories are an important trend to keep an eye on, too, says Brown. “As we emerge from the inventory correction that the entire industry has been experiencing, demand for plant-based solutions for hair- and skincare, energy, immunity, and digestive health have resumed their strong growth curves,” he explains.

As more manufacturers attempt to exploit the popularity of alternative dosage formats such as gummies, the more difficult it may become to stand out in an increasingly saturated marketplace. Experienced contract manufacturers can help brands find ways to differentiate from competitors as well as produce good-quality products.

“In this fast-paced industry of ours, it is definitely important to stay on trend, which is why, unfortunately, when a trend has been identified and set, everyone is able to jump on the bandwagon, and not many can deliver quality goods,” says Jeanroy. When it comes to dietary supplements, placing the onus on health is paramount. “Most gummies today are made to be palatable by being sweet. An important criteria to take into consideration is to develop gummies that are not detrimental to the health in the long run because for most on the counter today, the sugar content is the equivalent of that in a candy,” she explains. “This is the reason why all the gummies we produce at Activ’Inside are sugar-free, and there aren’t many manufacturers that can attest to that.”

Navigating the balance between health, low sugar, and good flavor is where an experienced contract manufacturer excels. “The dosage formats that provide the most pleasant consumer experience are the ones that have the strongest growth rates,” says Brown. “Sirio specializes in the variety of options we offer to customers and in flavors that delight consumers, which increases compliance and brand loyalty.”

Brand loyalty is crucial for growing one’s business. It means having a reliable customer base that is willing to explore other product options under the same banner. And as trends ebb and flow, contract manufacturers can help you expand and find success in other product offerings to further grow your enterprise.

Prinova acquires Aplinova to further increase its footprint in Latin America

April 7th 2025Prinova has recently announced the acquisition of Brazilian ingredients distributor Aplinova, which is a provider of specialty ingredients for a range of market segments that include food, beverage, supplements, and personal care.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)