Fermentation’s power to improve nutritional ingredients

How can fermentation boost the efficacy, longevity, bioavailability, and activity of skincare and wellness ingredients?

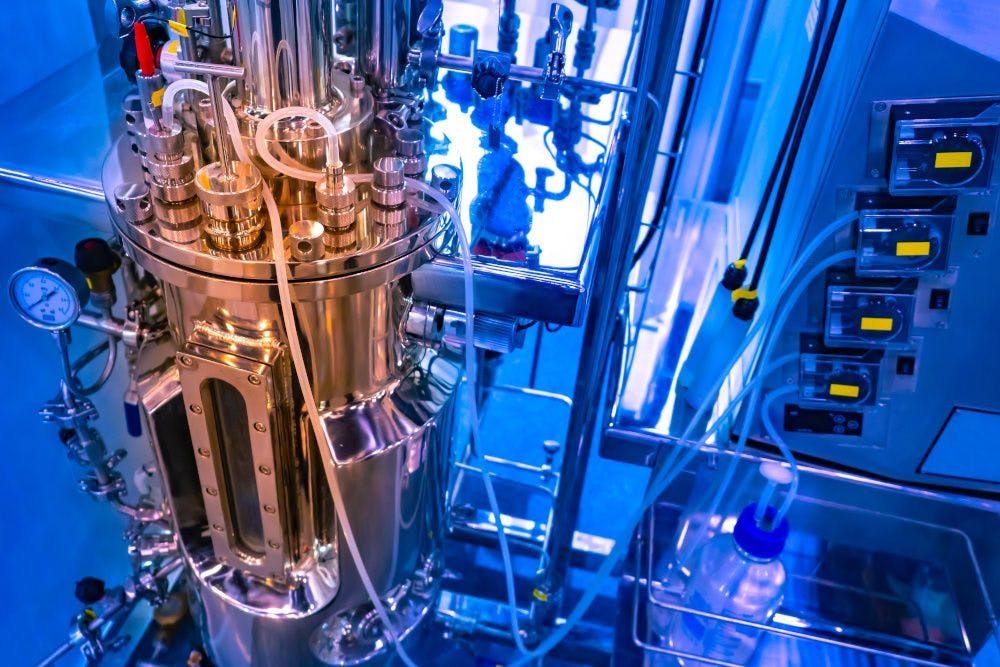

Photo credit © Grispb - Stock.adobe.com

Fermentation is such a force of nature—literally—that we couldn’t escape it if we wanted to. Fortunately for us, we don’t want to.

Because when carefully controlled, fermentation makes foods more flavorful, brings buzz to our favorite beers—it even grants grape juice immortality. It’s a transformative process as old as time itself.

But don’t let its age-old résumé fool you: Fermentation has some new tricks up its sleeve, and one of the more intriguing among them is an ability to act as ingredient potentiator—a physical and chemical master key that can unleash more efficacy, longevity, bioavailability, and sheer activity from already-active nutrition, skincare, and wellness ingredients.

This pays dividends for health-and-wellness brands and their consumers alike. And as product developers explore how to harness fermentation’s latest superpower, they could unlock whole new avenues of formulation potential, naturally.

Buzzed

The current buzz surrounding fermentation is hardly confined to the beer bottle or wine glass. Fermented foods, ingredients, and even cosmetic lines are generating a lot of…well, ferment.

Consider that Mintel included fermentation among its five U.S. ingredient and flavor trends1 for 2019, and that the restaurant-management platform Upserve tracked a 149% increase in fermentation menu mentions2 in 2018.

And while Elzaphan Hotam, vice president of global marketing and CEO, NextFerm USA Inc. (Berkeley Heights, NJ), interacts mainly with the B2B side of things, he’s privy to the rise in fermentation’s public profile, not just through his own experience but via that of his customers. “The feedback we get from brands is that fermentation is a powerful word that generally has a positive connotation with consumers,” he says.

Paul Schulick, cofounder of the microbiome-focused skincare line For The Biome (Dummerston, VT), agrees. “From twice-fermented beers that claim to support gut health to foods like kimchi and fermented herbal supplements, fermented products are all around us,” he says. “And like fermentation, they’ve been around since ancient times.”

Molecular Machinery

But what makes this latest fermentative renaissance different is the potential it has to transform not just finished foods and beverages like kimchee and beer, but the ingredients that go into them, and into a host of other products.

Hotam describes three approaches to using fermentation as an ingredient engine. “One takes everyday vitamins and minerals and allows yeast or other microorganisms to metabolize them so that they can later be introduced into a ‘natural,’ ‘whole-food’ matrix, to which they may bring better nutritional benefits, absorption, efficacy, and so on,” he explains.

A second strategy highjacks cells’ molecular machinery to produce target compounds via fermentation. The resulting cellular components, secreted molecules, or even entire cells themselves can be repurposed as supplement ingredients, Hotam continues, “and they’re a natural part of this organism.”

An example is NextFerm’s Astaferm brand of astaxanthin, which the company makes by taking advantage of the Phaffia yeast’s natural ability to express the popular antioxidant through fermentation.

“Finally,” Hotam says, “there are companies and technologies that use molecular biology to ‘plant’ foreign DNA into microorganisms like yeast and exploit their ability to propagate rapidly and produce a desired molecule efficiently. This is more common in the pharmaceutical market to make antibiotics, for example, but compounds made this way are also available as nutraceuticals.”

Fermentation’s Superpower

Precisely how these fermentation approaches potentiate an ingredient’s efficacy “is hard to explain in a general way since each compound and technology may have a different reaction,” Hotam concedes. But in brief, the natural synthesis and metabolism that occur during fermentation produce compounds with unique characteristics—perhaps a novel stereoisomer; differing degrees of methylation or esterification; maybe the presence of cofactors or other trace elements in the finished matrix—that strengthen the product as a whole.

In the case of Astaferm astaxanthin, for example, NextFerm’s process yields a form of the carotenoid that’s non-esterified and thus closer to the molecule that circulates in our bodies following ingestion, Hotam says.

Similarly, when For The Biome ferments botanical ingredients with select probiotic strains for its skincare line, not only does the potency of the individual ingredients rise, Schulick says; “New compounds are created that didn’t exist prior to fermentation, too. So, where you may have had a formula that nourished skin with polyphenols, you now get a formula packed with prebiotic and postbiotic nutrients that feed the microbiome.”

Even better, preexisting formulation compounds end up more stable. He adds, “It’s the ultimate solution to producing clean, green formulas that surpass the efficacy of both synthetic and natural formulas.”

All Plus Side

That’s a handy side benefit. And from Schulick’s perspective, it’s part and parcel of fermentation’s advantages.

“Nature’s wisdom is already complete,” he says. “So, the only way to increase ingredient potency and efficacy is to ensure that the integrity of each whole ingredient is retained. Fermentation is one of the best preparation methods to ensure that this happens.”

Among its other plus-sides, fermentation yields products that usually enjoy a longer shelf life than their unfermented counterparts. “For example,” Schulick says, “a fermented powder doesn’t require water prior to use, and the very absence of that water inhibits any unbalanced microbial growth that could occur, while sustaining the ingredient’s potency through the supply chain.”

Then there’s fermentation’s sustainability credentials, as the process exacts a relatively small price in energy, land, water, and other resources, Hotam says, “and in many cases uses food-industry waste streams as a major raw-material source.”

Closed fermentation vessels minimize ingredient exposure to the environment and maximize run-to-run consistency, he continues, “and these major advantages come atop what we’ve discussed: efficacy.”

Indeed, not only do the yeast and fermentation conditions that his company deploys yield flavorless, high-purity astaxanthin isolates; Hotam claims that the ingredient is highly potent and nutritionally superior, too, “expanding astaxanthin’s application to products like gummies, powdered premixes, and more.”

“However,” Schulick cautions, “not all fermentation is created equally.” Just as a degree of “greenwashing” plagues most industries today, examples of “fermentation-washing” are beginning to abound, he says.

In skincare, he’s seen a handful of brands promote fermented products, but wagers that only a slim percentage “deliver a true ferment”—as For The Biome does when it ferments all its ingredients together in a single batch, he says.

The spray-dried powders that result require no fillers or chemical preservatives, he continues, while liquid ferments require only radish-root ferment to preserve and stabilize the formula.

“This practice really streamlines the unnecessary, sometimes harsh, ingredients needed to preserve a formula,” Schulick says. “This cuts back on waste and only makes these products more compatible with the skin’s environment, to say nothing of making them more effective. A ferment is only worth the sum of its parts. When the best ingredients go in, the ethereal comes out.”

References

- Mintel press release. “Mintel announces five U.S. flavor and ingredient trends.” Published June 3, 2019. Accessed here.

- Upserve blog. “Restaurant menu trends: What’s hot and what’s overhyped for 2020.” Published on October 30, 2019. Accessed here.

Prinova acquires Aplinova to further increase its footprint in Latin America

April 7th 2025Prinova has recently announced the acquisition of Brazilian ingredients distributor Aplinova, which is a provider of specialty ingredients for a range of market segments that include food, beverage, supplements, and personal care.