Dietary supplement equipment outlook 2023: Equipment advances let dietary supplement manufacturers soar

What’s new in the world of equipment for dietary supplement processing and packaging?

Machines can work wonders. No one questions that the Industrial Revolution, the transition from people working by hand to working with machines, is one of the dominating economic forces in industry. Nutraceutical ingredient and finished-product manufacturers recognize the role that modern equipment and forward-thinking technology play in a thriving industry.

And yet, this past December, when McDonald’s introduced its new fast food test concept for drive-through and pick-up at a newly opened automated location in Texas, it raised this age-old question: can humans and machines still happily coexist?

Charles Ross & Son Company (Hauppauge, NY), an employee-owned, original equipment manufacturer (OEM), has been in the mix since right around the time that the first Industrial Revolution was coming to a close, the company having established itself in 1842.

Erin Dillon, media and marketing coordinator at the company, points out that Ross has been manufacturing mixers and blenders for over 180 years. So, as she puts it, “we have seen the ebb and flow of progress, technology, and global events more than your average company.”

In fact, as Dillon tells it, “The earliest Ross mixers replaced human operators manually stirring tubs of product. Fast-forward to today, most of our machines are supplied with advanced touchscreen controls and recipe systems.”

However, she’s not worried that machines will completely take over. “Ultimately, there are certain things machines just can’t do—at least not now—so I think the symbiotic relationship between man and machine will be safe for years to come,” Dillon says.

Volkmann Inc. (Bristol, PA) manufactures high-performance pneumatic vacuum conveyors, and the company’s vice president of sales and marketing, David Nichols, says it’s more likely that rather than humans being replaced, “we’ll see an integration where machines help people work more safely and with more efficiency.”

Nichols explains that “humans introduce a level of variance into the equation that quality-control professionals call human error, whereas machines usually operate with more consistency and repeatability—and, of course, usually at a lower cost structure.”

Volkmann’s PPC pneumatic vacuum conveying system. Photo from Volkmann.

But before it sounds like a win for machines, those benefits aren’t the whole ballgame. Even with the homeruns a machine can claim, Nichols states that “people are needed to design, build, operate, and maintain machines, so it’s unlikely we’ll see machines replace people as a whole.”

Nichols uses Volkmann’s conveyors as an example to make his point. “Our conveyers make it safer, faster, and easier to transfer ingredients to the mixer, for example, but even our conveyers don’t come up with the recipe, source the ingredients, verify the product quality, or sell product to a consumer,” he says.

As an example, Volkmann’s PPC pneumatic vacuum conveying system automatically captures tablets at the tablet press discharge and transfers them directly to the bottle filling line or to storage, according to a press release. The vacuum conveyor establishes a sealed, enclosed system, then carefully transfers the sensitive tablets without human contact or exposure to the plant environment to prevent chipping, scratching, breakage, and contamination while also leaving any dust behind inside the conveying system.

Score One for Machines Helping Keep Humans Safe

Process equipment manufacturer Automated Flexible Conveyor Inc. (AFC; Clifton, NJ) is one of the companies looking out for industry employees. In late 2022, AFC introduced the AFC SpiralFeeder Push Unit solid screw conveyor. According to a press release, it was developed to support worker safety by setting the drive mechanism at floor level at the hopper rather than at the discharge to invite easy access to the electric motor and gearbox without requiring a ladder, mezzanine, or other lifting device.

The AFC SpiralFeeder Push Unit solid screw conveyor, introduced in November 2022. Photo from Automated Flexible Conveyor Inc.

According to David Nadel, design engineer at AFC, “Anyone who’s had to lift an 80-lb bag over his or her shoulder and climb up a ladder to dump it into a mixer or some other piece of equipment knows how dangerous a processing plant can be.”

“As equipment designers,” Nadel continues, “we’re in a position to help address worker safety issues in a way that makes it easy for employers to improve working conditions while also improving overall process and plant efficiency. In the case of the Push Unit, the customer required a low-profile system that fit an existing area with low headroom. The safety benefits were important to the customer and very much appreciated after installation.”

The AFC SpiralFeeder automatically transfers powders, pellets, and other dry bulk materials from the hopper to discharge via a screw auger rotating inside an enclosed tube. And it does it all carefully.

It’s useful in dietary supplement plants “for transferring vitamin powder blends to a tablet press, where they excel at safeguard particle size and shape and at keeping blends blended during transfer,” says Nadel.

While this sit-at-floor-level equipment line likely won’t replace all traditional machines that require use of a ladder or other lifting devices, it’s certainly a welcome addition, with benefits that go beyond its safety profile. For example, Nadel points out that price is another advantage of the AFC SpiralFeeder. “We price it at the lower end of the conveying equipment spectrum so anyone operating a dietary supplement processing line can take a look at it without hesitation about the investment,” he says.

Nadel also believes that customers appreciate options. He says that “many years ago, most manufacturers built standard machines, and it was up to the customer to make it fit into the process. Today, most of our industry customers need to maximize every inch of floor space, so we design our screw conveyors to fit into tight spaces and odd configurations as needed. They also need to produce a wide range of products in a variety of sizes, so we make sure our conveyors can be quickly disassembled and cleaned for changeovers.”

New Compact Mixer Joins The Line

AFC is not the only company pumping up smaller-sized equipment.

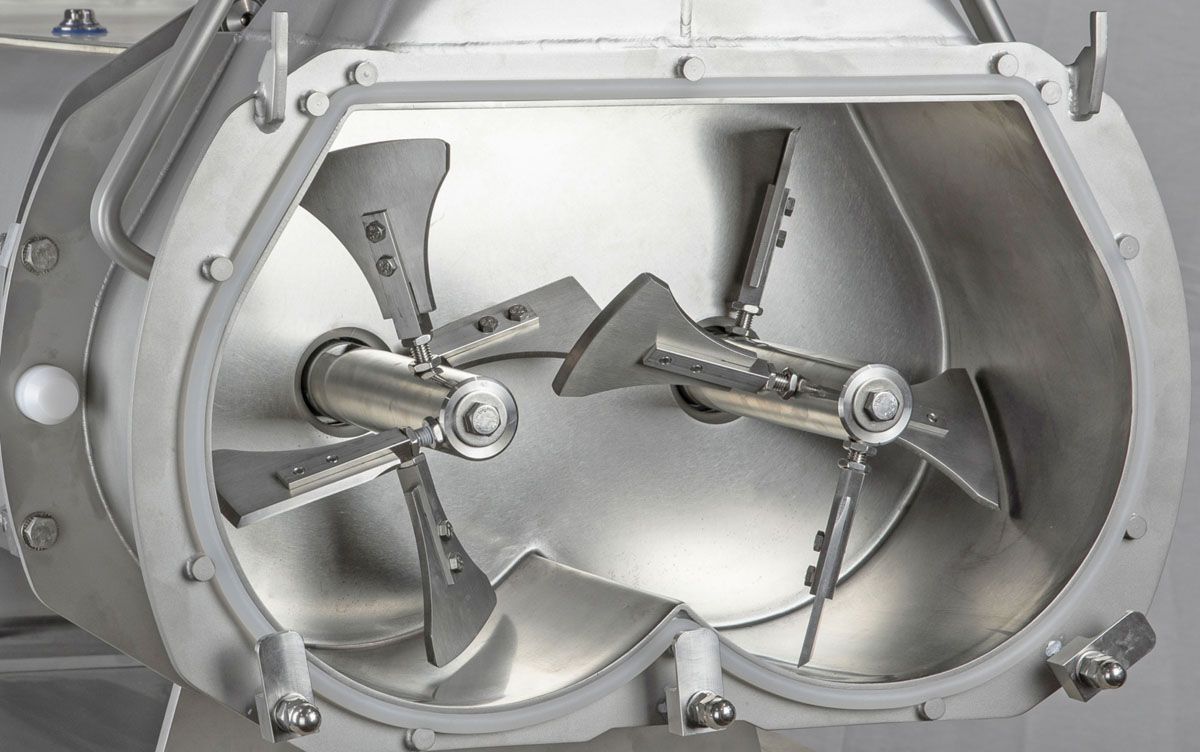

Gericke USA Inc. (Somerset, NJ), a multinational process equipment manufacturer, in April 2022 introduced a compact model mixer to its Multiflux line, bringing the number of options in the line to seven models, plus custom designs. The Multiflux GMS Laboratory Mixer uses the company’s proprietary double rotor design already proven in its line of high-volume mixers. According to a press release, the GMS Laboratory Mixer was developed to offer the same high-speed, gentle, and hygienic mixing capabilities in a low-volume, tabletop model.

A closeup of the mixing tool inside the mixing chamber of Gericke USA’s Multiflux GMS Laboratory Mixer tabletop model. Photo from Gericke USA.

Fabian Müller, PhD, product manager, mixing, for Gericke, says the new compact mixer can be used for research and development purposes, premixes, and small production quantities.

For example, he explains that “since the development of new formulations uses low volumes, this mixer enables challenges in production to be identified early. Then formulations can be adjusted and tested again, quickly and in low volumes, before any major investments have been committed.”

“Consider a small vitamin and dietary supplement company that specializes in custom, small-batch formulations,” suggests Müller. “The Multiflux GMS Laboratory Mixer tabletop model would allow them to efficiently and accurately mix the ingredients for these formulations, without the need for larger, more expensive mixing equipment.” He adds that for a startup company developing its own line of dietary supplements, the tabletop model “would be a cost-effective and space-saving solution for producing small quantities of their products while they determine their product offering and finalize the formulations.”

In comparison to the larger models in the existing lineup which accommodate usable volumes up to 4,000 liters, the GMS Laboratory Mixer accommodates usable volumes from as low as 1 liter up to 20 liters. The machine automatically directs the materials into a fluidized zone for fast, but gentle, interactions to achieve a homogenous mixture in cycle times of 30 seconds or less, even mixing materials in small quantities below 0.01%.

The fluidized zone is achieved by using two horizontally arranged, superimposed, counter-rotating mixing tools, says Müller. “This design enables extremely high radial and axial transfer rates, resulting in the highest levels of homogeneity.” The mixer, he says, “operates at the optimal Froude number of 1.2, where the centrifugal forces exceed gravity forces.”

The new, compact GMS Laboratory Mixer can be used inline or as a standalone unit, says Müller.

How Gummies Are Counted Counts

Cremer (The Netherlands), a leading supplier of product-counting machines in the U.S. for a wide array of applications, introduced its HQS 1250 Counting & Dispensing Machine, designed specifically for gummy applications in the nutraceutical (and confectionery) sectors, according to the company. With over 40 years of experience in the pharmaceutical market, Cremer introduced its gummy solution in partnership with filler manufacturer Spee-Dee. The new 12-lane counter can precisely apportion gummies of all shapes and sizes to a downstream bottler or single belt setup. With an average output of 150 bottles per minute on a 60-count gummy product, the HQS 1250 is ideal for a wide variety of gummies in typical sanded or sugared formulations, the company says.

Cremer’s HQS 1250 Counting & Dispensing Machine was designed together with Spee-Dee specifically for nutraceutical gummies.Photo from Cremer.

Rene Stuijt, business manager, industrial, for Cremer, says the need for gummy production, both from a primary and secondary manufacturing perspective, has become greater along with the rise of nutraceutical gummies over the past few years. “Cremer has supplied gummy counting/filling systems in the past,” he advises, “but they were lower-speed or more geared towards candy gummies and not nutraceutical gummies.”

Cremer’s HQS 1250 series of gummy counters addresses the demand to reach high-speed output with accuracy in the nutraceutical market, notes Stuijt.

“In conjunction with a Spee-Dee rotary filler, we are able to achieve a throughput speed of 150 bottles per minute on a 60-count gummy fill,” Stuijt shares. In addition, he asserts that “what makes this system unique and sets it apart from the competition is 100% counting accuracy with sugarcoated or sanded gummies at high speed, as well as the elimination of bottle clogging during the filling process.”

Stuijt reveals that “the system took time to develop because Cremer had to adapt our signature counting technology to suit harsher environments featuring sanded and sugarcoated gummies. It also took the right partner in Spee-Dee to develop the corresponding bottle filling and transport systems.”

Counting gummies presents some unique challenges—the separation of the products, for one, according to Stuijt; another being the collection of the sugar leave-behinds and other residue. Stuijt advises that “if the products are too sticky and cannot be separated, then we cannot count them accurately. If there [are] onerous amounts of sand and sugar, this can wear out the internal parts of the machine faster.” Cremer’s equipment solves that problem, he says.

In addition, Stuijt points out that “running different shapes and sizes is not a problem [with their latest machines] as change parts (vibratory plates) can be swapped out by a line operator without the need for tools.”

Stuijt says that the market has been very responsive to this new technology development. “We currently have two complete systems in production with a major U.S. co-packer and are looking to further expand in the marketplace,” he adds.

Technology Advances Count, Too

Like so many other industries, equipment manufacturers are focused on technology discoveries and improvements that go hand-in-hand with new machine introductions.

Ross’s Dillon considers that most advancements in recent years in process equipment have been incremental, progressing toward greater efficiency. “While there have been few major changes in the physical components of process equipment,” she says that “the controls side has evolved exponentially. New software, control systems, and user interfaces are being implemented in order to promote higher product yield, lower production costs, longer service life, better monitoring, automatic data logging, and improved operator safety.”

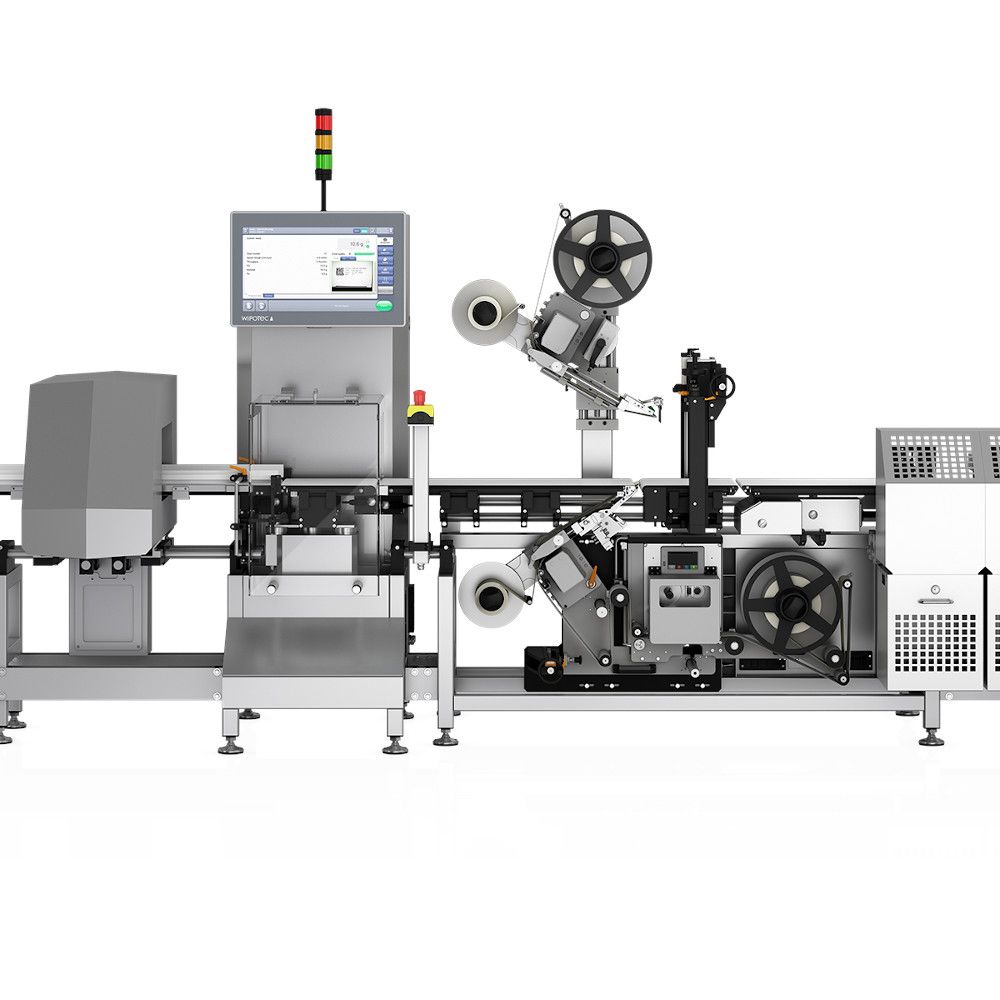

Wipotec-OCS Inc. (Lawrenceville, GA), a leading manufacturer and supplier of precision in-motion weighing, X-ray scanning, and other equipment, last year introduced the company’s Traceable Quality System Modular Design (TQS-MD) line. According to Daniel Brandao, regional sales manager, southeast, healthcare industry, “The TQS-MD combines all of the inspections required by the nutrition sector.”

For the dietary supplement industry in particular, it’s the modular aspect that is especially appealing, says Brandao, because the building-block concept allows a company to link to the segments of equipment that are most applicable, whether it’s metal detection, checkweighing, marking, verifying, labeling, or more. Brandao says that “it can all be rolled into a single compact system with optimal software controlling it. It’s the way it is controlled by the TQS software that makes it stand apart.”

Wipotec-OCS’s Traceable Quality System Modular Design (TQS-MD) is compatible with a broad range of equipment. Photo from Wipotec-OCS.

As Brandao explains, “The TQS software allows for centralized control of all inspection processes on the machine, with all parameters for each inspection process maintained in separate recipes that can be applied to a group of SKUs or uniquely for each SKU. These parameters can change the speed of the line, allowable weight range, and even turn off a specific process that may not be required for that SKU.”

Further, he says that line operators do not need to learn how to operate individual human-machine interface (HMIs) for each inspection process. “This helps simplify the setup of new products and order changeovers,” Brandao adds.

Supplement and functional food industry customers may consider whether they will also find value and relevancy in other aspects of the software. For example, Brandao notes that the software behind the TQS system was designed for pharmaceutical serialization printing requirements, where UPC barcodes are being replaced with 2D data matrices. He understands that “while this doesn’t offer much value for the nutrition sector currently,” it does mean that the TQS systems are prepared for the retail industry barcode transitions set for 2027 by the retail industry in collaboration with GS1 US to equip retailers—and consumers—with more information about the products they buy.

Brandao states that “some of the largest retailers are already working out the kinks with an upgrade from the UPC to the 2D codes, and the TQS systems offer companies the capability to keep up with this major packaging change.”

On the production side, Brandao observes that a TQS-MD system has the ability to save actual product weights measured and the metal detector pass/fail results for each serialized product inspected. “This data can be saved in batch order and retrieved at any time in the future,” he advises. “Customers currently using this can reduce errors or inefficiencies in production and reduce the cost and time of recalls should any occur,” he adds.

Sales and marketing departments, too, will be able to acquire more granular data on the products they represent, according to Brandao. And as for retailers and consumers, he shares that “scanning a serialized code, one would now be able to learn the exact times and quantities that a product is purchased, as well as locations where consumers interact with any marketing efforts embedded into the 2D code.”

Brandao says this data is currently available to a certain extent, but the quality of information greatly increases with the software associated with the Wipotec-OCS TQS-MD machines.

Novel Bottle-Handling Technology

The Deitz Company (Wall Township, NJ) is a 60-year-old family-owned and -operated packaging machinery manufacturer. According to the company’s technical product manager, Dan Deitz, the company prides itself on “offering reliable equipment that’s easy to use at an affordable price point so growing companies can automate one step in the process at a time and add more as business grows.”

Among the many products the firm manufactures to help customers are the Pharmafill TC3 capsule counters that incorporate novel bottle-handling technology that enables tablet-counting machines to be linked in series for increased capacity and faster production rates. According to a press release, the Pharmafill TC3 is suitable for counting and filling capsules, softgels, caplets, pills, and more, and helps customers match production requirements to the batch volume or continuous run of tablets at any given time through the proprietary index timing technology that automatically controls and directs the flow of empty bottles from a conveyor or two or more electronic tablet counters.

The Pharmafill TC3 counter from Deitz features novel bottle-handling technology. Photo from Deitz.

What Deitz particularly likes about the product is that the automatic counter that “features our proprietary counting sensor can accurately count nearly any type of solid dosage form, even clear gel caps that are virtually invisible, with 99.99% accuracy.” With just one counter, he says, “a supplement company can count and fill nearly any or all of its products. Plus, we include casters as standard so it can roll up to any conveyor and be ready to run in just a few minutes.”

When it comes to his customers and potential customers, Deitz suggests that “growing companies like having access to the same counting technology as in our fully automated TC3 that very big companies use—but in a compact, semiautomated model they can set on any table or countertop.”

He explains that with the TC4 model, “one operator sets empty bottles at the discharge, then removes them when filled every few seconds and repeats the process. Owners of some companies do this themselves. In other cases, an entry-level employee does the counting and filling so management can focus attention elsewhere. Its user-friendly design makes it very easy to learn and use, and it can be adjusted to the working speed and style of the operator in seconds.”

What’s in Store from Equipment Manufacturers in 2023?

Custom designs are always in fashion, and machines are no exception. For companies concerned about the cost of customization, Dillon acknowledges that while cost is always a consideration, “the first step should begin with proper mixer selection, because most products can be made using a variety of mixing equipment and manufacturing methods. Some just work better than others.”

But, as Dillon says, “once the proper mixer has been chosen, it can be customized to meet a variety of requirements at different price points.”

Dillon believes that taking the time and effort to determine the best mixing strategy for customers is key. And, she advises that “we have a state-of-the-art Test and Development Center that allows customers to see, in real time, how Ross mixers can improve their product and/or process.”

From Volkmann executive Nichols’s perspective, “the move to automation is not going away.” In fact, he shares that “companies that tested the waters automating one or two steps in a process have seen enough improvement to look into automating more and more of the process.”

Nichols finds that his company “gets calls from customers with our conveying systems who want to get the same systems for their other plants, or they want to add our auxiliary equipment to automate bulk bag unloading, for example. As long as the labor market remains a challenge, and as long as owners and managers want to provide a safe workplace, then automated equipment like ours will be in demand.”

Nichols says that in 2023, Volkmann is planning to introduce “our latest vibratory feeder for accurate weighing and dosing ingredients into a process or filling line.” He adds that “a lot of companies are wasting a lot of product with inaccurate weighing and dosing, and with the rising cost of ingredients, it’s important to pay attention to every step in the process and find savings wherever possible.”

AFC’s Nadel also sees automated equipment continuing to gain favor in 2023. He says that “as a manufacturer of automated equipment, it’s easy to say that ‘we see demand for more automation in 2023’—but that’s exactly what we’re seeing.”

Nadel explains that “a lot of manufacturers and processors are still struggling with staffing, and automated equipment like our AFC SpiralFeeder helps protect companies against workforce uncertainty.” As far as new equipment in 2023 is concerned, Nadel articulates that “we’re design engineers, so we’re always working on new ideas.”

At this point, Nadel notes that AFC is “planning to introduce another sanitary version of the AFC SpiralFeeder that would comply with the most demanding levels of clean any test and inspection manager might require.”

Deitz says that “the dietary supplement industry has been taking a large chunk of business away from the pharmaceutical industry for years, and 2023 will be no different.”

He believes that “as more and more of these young businesses see success, their owners can reinvest in their operations.” He adds that “given the state of staffing issues today, many are reinvesting in new machinery and equipment, moving away from manual filling and packaging that demands a lot of human resources.”

It’s no surprise that Deitz, too, is a fan of automation, and he sees his customers “pushing forward towards automated processes that can work faster, 24/7, with little or no supervision.” He advises that later this year, “we’re planning to roll out a brand-new line of inspection equipment to help companies prevent errors in cotton insertion, tamper-evident-band application, and several other operations.”

As for Cremer, Stuijt says that dietary supplement manufacturers can expect a new range of intuitive, flexible, and efficient standalone bottle packaging machines in 2023. “It will start with the new BU 300 Bottle Unscrambler, which is ideal for feeding small and medium batches of round or square bottles upright into a production line,” he advises.

Cremer also has plans to introduce an inline bottle capper, dubbed the BC 200 Bottle Capper, which can apply caps with an accurate torque or press-on force at a pace of up to 200 caps per minute, according to Stuijt.

He shares that both machines offer gentle bottle handling, easy maintenance, and cleaning with a central intuitive HMI with Smart Control, enabling user-friendly operation, easy reporting, statistics, and connectivity to other machines. Stuijt adds that “all these factors will contribute to a particularly high economic efficiency.”

Dillon also reminds us of the pandemic’s lasting mark. She says that “as product demand increases and workforce challenges arise, the top priority of most of our customers in this late phase of the pandemic is production floor efficiency. The pandemic exposed several weak points in the supply chain, but it has also opened up a world of possibility.”

Prinova acquires Aplinova to further increase its footprint in Latin America

April 7th 2025Prinova has recently announced the acquisition of Brazilian ingredients distributor Aplinova, which is a provider of specialty ingredients for a range of market segments that include food, beverage, supplements, and personal care.