Dietary Supplement Machines for Modern Manufacturing

The supplement industry has been on a tear lately. Explicit evidence of this comes in the way of cold, hard statistics-like the projection, reported in Nutrition Business Journal, that the category’s approximate $32 billion in 2012 revenue will likely double to more than $60 billion by 2021. As for implicit proof, though, look no further than the widening variety and sheer braininess of the dietary supplement manufacturing equipment now coming online.

From her perch as application engineer at Charles Ross & Son Co. (Hauppauge, NY), Christine Banaszek views the industry’s expansion through the prism of evolving mixer and blender design. “Within the last decade,” says Banaszek, “we have witnessed tremendous growth in supplement manufacturing. This is demonstrated not just in the increasing demand for mixing and blending equipment year after year, but also in the special mixer features and customizations that more companies are willing to invest in.”

Examples include the latest generation of high-shear rotor/stator mixers-capable of subsurface powder induction for faster and more efficient wet-out of solids-and sanitary ribbon blenders with close-tolerance agitators and scrapers that eliminate product “dead zones.” Banaszek says that clean-design double planetary mixers, whose helical blades mix viscous pastes and gels while reducing contamination, are also proving popular. But there’s more.

“We’ve also expanded our offerings of pneumatically-controlled, dust-tight valves; customized vacuum covers; bag dump stations; automated discharge systems; and sophisticated PLC (programmable logic controller) operator controls,” says Banaszek. “Manufacturers appreciate how optional features like these help them mix multiple recipes with consistent results, shorter changeover periods, and less room for operator errors.”

Consistency, efficiency, accuracy, and safety: these are the issues that equipment suppliers are partnering with their customers to address. In the process, equipment suppliers are better positioning supplement makers to get the most not only out of their machines, but out of their entire operations, as well.

Flex Time

Thomas Mauritzen, business development manager of pharmaceutical operations at Bosch Packaging Technology Inc. (Minneapolis) says, “One of the greatest needs that we see in the nutritional supplement manufacturing industry is the need for speed, flexibility, and the ability to run a wide range of products.”

These goals were often just out of reach in the past, in no small part because of the era’s equipment itself. With their “much lesser GMP design,” as Mauritzen describes it, previous generations of machinery were known to “create difficulty and extended time requirements for cleaning and changeovers.” This translated into longer downtimes and limited machine availability for production.

Consider, for example, the overhead segment turret cam on earlier models of his company’s encapsulators. The design feature represented a challenge for cleaning and disassembly of machine components, Mauritzen says, so his company has since eliminated it in favor of completely separated mechanical and production cabins.

Clean Machine

Such modularity allows for quicker, easier cleaning of today’s more GMP-compliant machines-an advance that would likely please Dale Natoli, president of Natoli Engineering Inc. (St. Charles, MO). Asked where he sees room for improvement in supplement manufacturing, his answer is “cleanliness.”

This applies especially to tablet presses, which Natoli says are much more effective and efficient when the machines are stopped on a scheduled basis to be cleaned, vacuumed, and lubricated properly. Removing the dust reduces common production problems such as binding, and tablet defects such as black specks or other contaminants that can fall into the product.

The Magic Formula

Lax cleaning and maintenance not only sap a product of quality, introduce potential safety risks, and chip away at efficiency; they shorten a machine’s operable life by increasing wear and tear, too. Emerging factors are stressing equipment in ways that weren’t common in earlier eras.

Supplement manufacturing has become more challenging, as a lot of manufacturers are trying to create and produce niche products. The challenge of niche production, says Natoli, stems from the products’ formulations, which create more variables, such as compressibility and abrasive wear. “With formulations today, nutraceutical manufacturers are compressing more minerals and herbs,” says Natoli, “which have a tendency to be more abrasive and reduce tablet compression tooling life.”

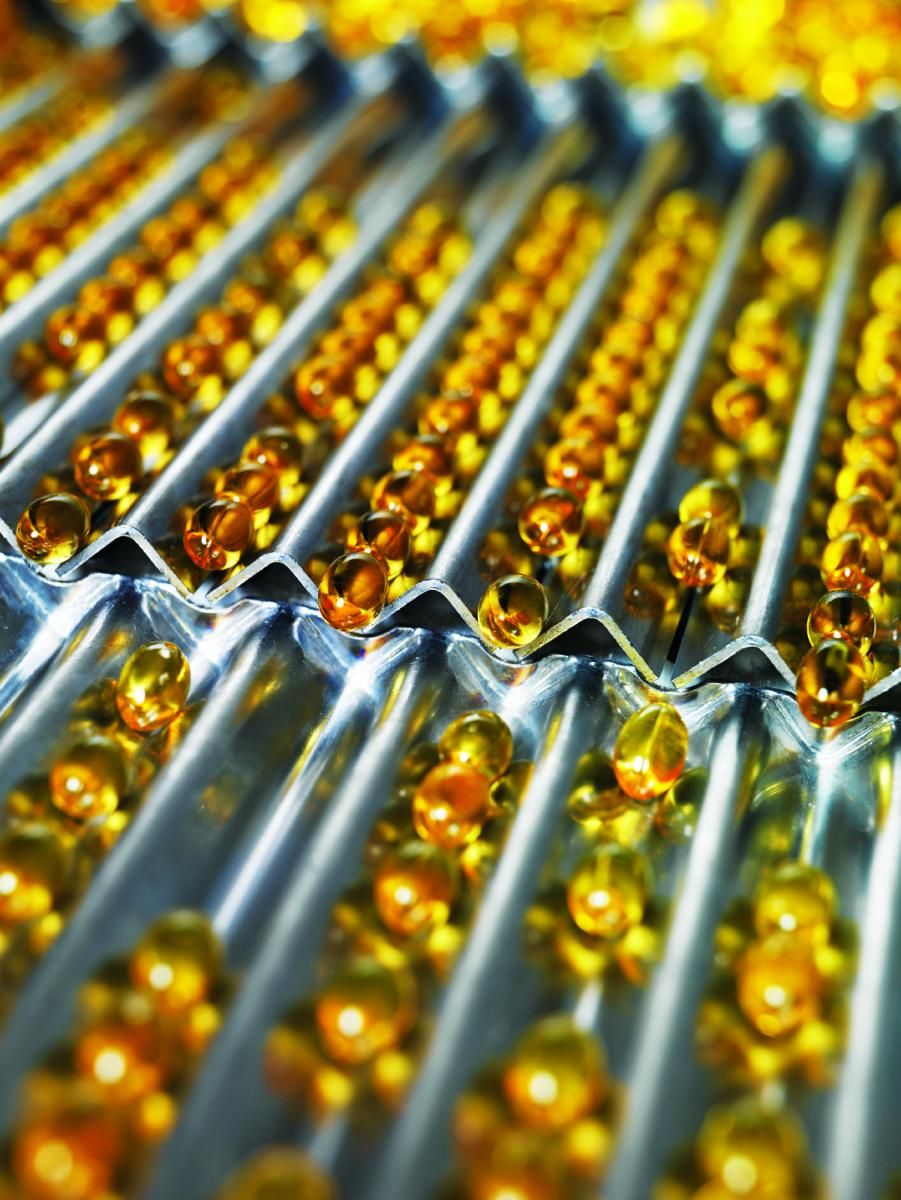

Steve Holtby, president and CEO of Soft Gel Technologies Inc. (Los Angeles) says that when manufacturing soft gels, “It is important to consider both the physical and chemical properties of a formula.” Soft gels, he says, are a “specialty delivery form,” and, as such, aren’t optimal for every supplement formulation. It may be that insufficient space within the capsule disqualifies a certain formulation, as in the case of protein supplements; also, potential interactions between low-pH ingredients and the gelatin shell itself might be limiting factors. In any case, Holtby says, “We always try to work with our customers to help them understand the importance of choosing the appropriate delivery system.”

Mauritzen adds that as manufacturers strive to run a wider variety of powder products-many supplement companies have hundreds or thousands of different products that they run-selecting a machine to accommodate the greatest variety, while still granting production flexibility, becomes paramount. “Both our tablet presses and tamping-style encapsulators provide extensive capabilities in handling fluffy, sticky, poor-flowing, and other difficult powders,” he says.

Keeping Up with the Competition

Tablet presses themselves have advanced dramatically, giving the manufacturer control over parameters like tablet hardness, thickness, and weight. And as actual tablet speed increases, efficiency does too. Natoli credits this increased efficiency with making domestic nutraceutical manufacturers more competitive as a class-and that’s no mean feat.

“The newer configuration of tablet compression tooling lets them compress more than one tablet at a time,” says Natoli. “With smaller tablets such as amino acids and B vitamins, you can run those on a multi-tip punch configuration, which increases your efficiency and doubles your production.” This reduces cost, saves energy, and cuts manufacturing times, which are changes any supplement maker should be happy to make.

Accuracy Counts

Today’s leaner operations not only seek to eliminate wasted time; they target wasted materials, as well. And here, too, smarter equipment is giving manufacturers an advantage. “One example of this is accurate dosing,” says Mauritzen. “If the filling/dosing equipment can provide a very accurate fill/dose, there is likely less waste in the process. Likewise, if the manufacturing equipment can create less waste-less powder lost when filling capsules or pressing tablets-the machine yields increase, and sellable output increases.”

On the end of the production line, checkweighers give manufacturers an invaluable tool for quantifying weight, a key measure of quality. Mauritzen says that a focus on quality often leads to an emphasis on fill accuracy, and can lead to the need to checkweigh 100% of product. While his company has produced capsule checkweighers for decades, it’s seen greater interest from the supplement industry in the last couple years.

Onward and Upward

And in an environment where the supplement manufacturer who’s standing still is already falling behind, savvy equipment choice can speed and smooth the transition from pilot testing to a first successful production run.

For example, Natoli says that using a tablet press simulator is an effective method to help determine how a product is going to run in real time during manufacturing. “Using this as a test in the R&D phase will allow manufacturers to compress a tablet to better mimic the dwell time and cycles of a high-speed tablet press, which will help reduce problems during scale up,” he says.

Mauritzen points out that because the machines in his company’s Capsylon series of capsule fillers all run at the same speeds-140 RPM, irrespective of whether the output is 42,000 capsules per hour or more than four times that amount-the only thing that changes when going from a small batch to a large batch is the number of capsules you produce. “This allows for an easy scale-up because the forces put on the product during filling are very similar,” he says. “Therefore performance should also be very scaleable.

Decision Time

So, what should supplement manufacturers ask themselves and their equipment suppliers when shopping for the ideal operational setup?

When it comes to mixers, Banaszek says, the selection hinges on many factors, including viscosity profile, density, shear requirement, heat sensitivity, friability, order of addition, and so-on. With so much to consider, she encourages manufacturers to kick the tires some. Take advantage of testing services and rental programs to confirm the best mixing strategy for your particular formulation, she says.

Because even the smartest contemporary machine can’t run itself entirely, finding equipment that’s compatible with your labor force-and teaching that labor force how to operate it-is more crucial than ever, especially in companies with high employee turnover rates and multiple machines in use.

As Natoli says, “Training is very important. In our experience, we see a deficiency in operational knowledge from online manufacturing operators.” As a result, supplement makers should prioritize user-friendly features, he says, and “establish an effective training protocol. They should ask if their equipment manufacturer can assist them in developing effective training processes, procedures, and protocols.”

In the end, the best advice for navigating today’s equipment landscape may be elementary: “Find the right tool for the right job,” Mauritzen says. It may sound obvious, but “a flexible, modular, speed-appropriate, and GMP-designed piece of equipment,” he says, “can have a large impact on improving overall manufacturing yields and efficiencies.” Like the supplement industry itself, it’s an idea whose time has come.

The Nutritional Outlook Podcast Episode 39: Nutritional Outlook's Ingredients to Watch in 2025

February 25th 2025In this episode, Nutritional Outlook interviews Scott Dicker, market insights director from market researcher SPINS, about ingredients and product categories nutraceutical and nutrition product manufacturers should watch in 2025.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)