Quality Control and the Benefits of In-House Manufacturing

Companies who choose to invest in in-house manufacturing may see unique dividends, says one equipment supplier.

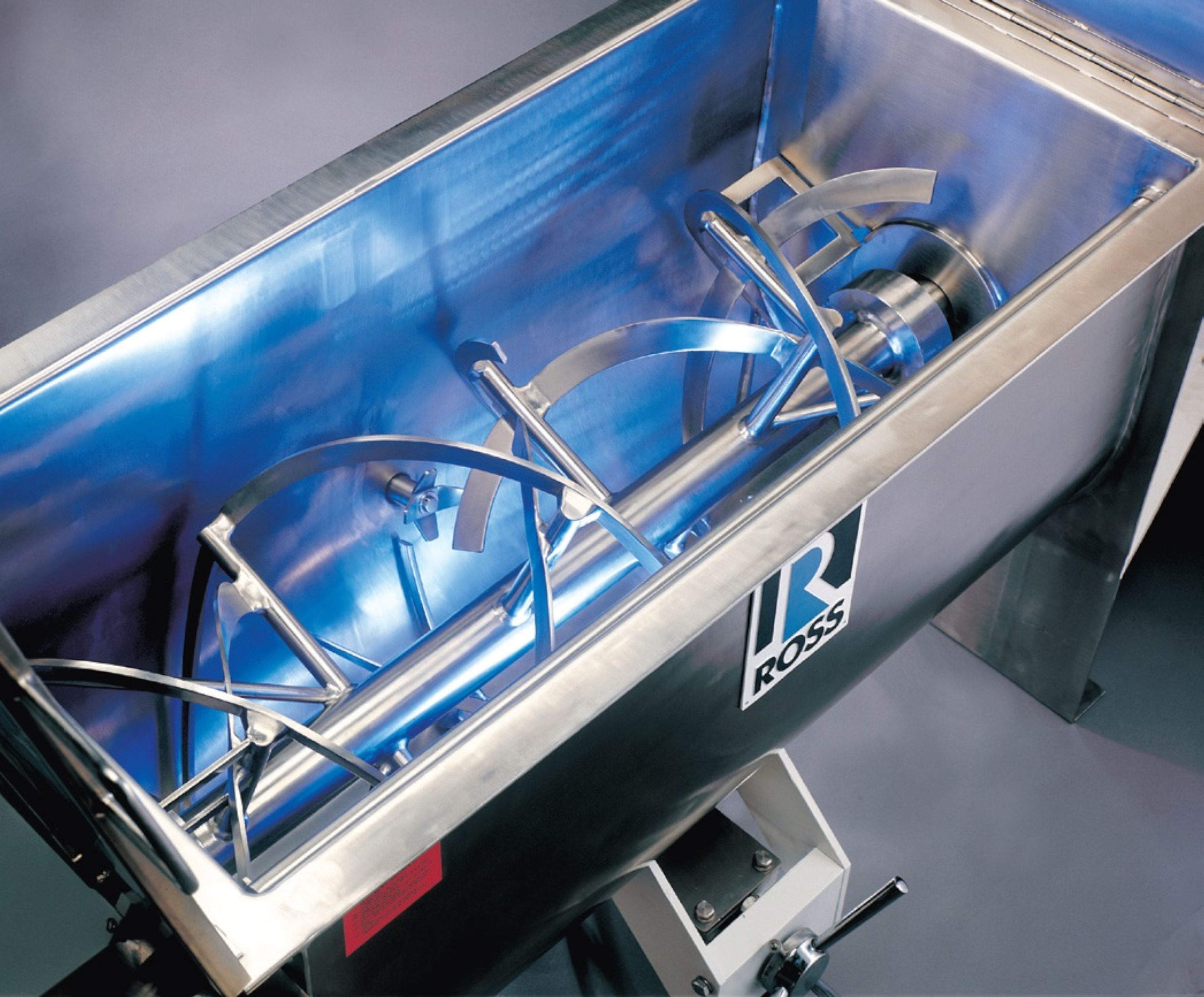

Pictured: By purchasing their own equipment and manufacturing in house, dietary supplement companies can control quality firsthand. Pictured: Charles Ross & Son Company’s Ribbon Blender Model 42N-5S

Selecting a product manufacturer is one of the most important decisions a dietary supplement marketer will make. These days, that decision is even weightier amidst heightened regulatory scrutiny and public attention on the supplements industry at large. With so much riding on the line, some nutraceutical firms are choosing to bring manufacturing in house in order to control, firsthand, the quality manufacturing of their products. While third-party contract manufacturers are still a valuable cog in the supplement production chain, removing the middleman can yield firms who choose to go in house some unique opportunities, says Ken Langhorn, technical director for mixing and blending equipment specialist Charles Ross & Son Company (Hauppauge, NY).

The Need for Secrecy

Take the guarding of intellectual property. Faced with an ever-widening landscape of competitors, today’s supplement firms increasingly seek to protect their formulations, ingredient blends, and material sources. By keeping the process in house, a company can maintain the utmost secrecy.

“People are more concerned about competitors popping up and copying their products,” Langhorn says. “We see people bring processes in house because they don’t want to send that information to a toll manufacturer where that technology could potentially be shared with other people.” This sharing may not even be done intentionally, he points out. “A toll manufacturer may be producing blends for several different clients, and their knowledge of what’s in one person’s blend compared to another’s may inadvertently cause them to make recommendations that would be a breach of that confidentiality.”

Advanced Machinery Enables Advanced Quality Control

Once a company does make the decision to manufacture internally, the company will need equipment that enables the firm to control quality. Luckily for today’s supplement makers, many types of equipment on the market today come with quality control built in.

Ross’s own mixing and blending technology, for instance, features built-in manufacturing and batch-production documentation controls. If FDA inspectors should knock on a supplement manufacturer’s door, says Langhorn, “the control system knows what was added in the batch record and then creates the batch record of how long it ran, when it was batched, and confirmation of the ingredients. It then stores that information in an unalterable document so that when FDA comes in, they can pull those unalterable documents and see for certain how each batch was processed.”

“It takes a lot of the liability, a lot of the paperwork, out of the equation, and that’s appealing to a lot of customers that have to comply with FDA,” he adds.

Understanding Industry’s Needs

Perhaps one of the most important ways in which equipment suppliers help today’s dietary supplement manufacturers is simply by understanding their needs-their needs for quality control, for regulatory compliance, and for bigger and better production. Langhorn points out that most of Ross mixers and blenders are custom-tailored to a company’s production needs, taking into account such parameters as horsepower, bulk densities, intended (and future) batch sizes, and the diversity of ingredients to be blended, including the ratio of active to inert ingredients.

Not all companies are ready to jump in all at once, of course. Some firms “start off on a small scale and say, ‘We’re going to bring some of this in house.’ And all of a sudden, they’re ramping up to larger blenders to bring it all in house,” Langhorn says.

As conversations around quality and safety continue to develop in the dietary supplements field, equipment suppliers will continue to play a key role in the discussions.

Prinova acquires Aplinova to further increase its footprint in Latin America

April 7th 2025Prinova has recently announced the acquisition of Brazilian ingredients distributor Aplinova, which is a provider of specialty ingredients for a range of market segments that include food, beverage, supplements, and personal care.